How Asphalt Pavers Work

Asphalt Pavers Work

When you are installing new asphalt pavers in your home or business, it is important to understand how they work. Asphalt is a mixture of crushed stone in varying particle sizes coated with bitumen. Asphalt can segregate easily if not handled properly, so you need to ensure that material flow is optimal from truck to paver. The design of the material hopper is also essential for continued transport of the mix.

Another important aspect of operating Asphalt Paver is the type of material you will be using. Most pavers are designed to accept Hot Mix Asphalt (HMA) directly from trucks, which reduces the time trucks spend at the paving site, and it also minimizes temperature differentials and aggregate segregation. A material feed system on a tractor is used to distribute the HMA to the desired width, which prepares the paver for compaction and screed leveling.

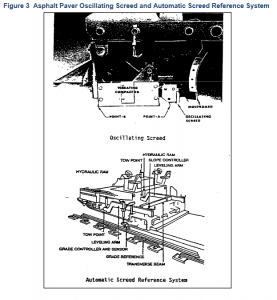

Modern asphalt pavers come with many features, including an engine, hydraulic drives, drive tracks, a hopper, a feed conveyor, and a screed. These devices help create a level base course and prevent future cracking. These tools are also equipped with sensors that measure slope and grade.

An operator is responsible for controlling the speed of the conveyor and adjusting it as necessary. In some models, a flow control system is used to regulate the amount of asphalt fed into the augur distributer. However, modern pavers are also equipped with automatic feed controls that regulate the amount of asphalt fed into the auger without the operator’s input.

How Asphalt Pavers Work

Automatic control systems can control the grade of an asphalt paver by adjusting various parameters. A paver’s speed, the rate of material feed, and the tow point elevation all affect the angle of the screed arm. This also affects the thickness of the mat. Automatic controls on pavers can also maintain a proper angle of the screed arm and keep the mat level and smooth.

A paver can be equipped with extensions that allow it to adjust the width of its mat. Basic screed widths range between 2.4 m (8 feet) and three meters (10 feet). There are rigid and hydraulic screeds available for certain pavers. These pavers are often towed by a tractor. Flow gates and sensing devices are used to control the speed of the paver.

The first mechanical paver was invented in 1931. The technology behind asphalt pavers has changed dramatically over the last century. Today, mixed asphalt pavements are much more durable than macadam pavements. This type of pavement is made of aggregates that are laid before being sprayed with a binding material.