Are pcb assemblers more expensive than traditional PCBs?

pcb assemblers more expensive

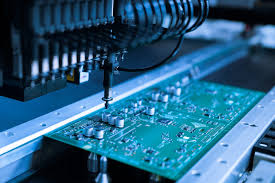

Assembling a printed circuit board (PCB) requires mounting small components to ensure that it functions in the way you require it to. It is an essential step in creating a complete electrical project, making the quality of the PCB a significant factor in its overall success. As a result, it is crucial to know how much to expect from your assembly supplier and the varying costs involved.

The cost of a PCB can vary depending on many factors, including the industry it serves, the type of product, and the assembly method used. For example, a pcb assemblers using through-hole technology is cheaper than one assembled with surface-mount devices. The number of layers and the thickness of the materials also play a role in the final cost.

Whether the PCB will be manually or automatically assembled is another major determinant of its cost. Manual assembly is typically used for prototypes and low-volume production runs, as it does not require extensive automation or specialized equipment. However, it can be time-consuming and inefficient, especially when producing multiple boards at a fast pace. It can also lead to mistakes, leading to an increased assembly cost per unit.

Are pcb assemblers more expensive than traditional PCBs?

Automated assembly is more expensive upfront due to initial investment in equipment, but it can significantly reduce costs by eliminating human errors and increasing productivity. Moreover, it can ensure consistent quality, improving the lifespan of your product. Choosing an automated process will also help you avoid the extra fees associated with manual assembly, such as component removal and rework.

When choosing your assembler, consider their experience and expertise. A qualified professional will be able to provide valuable advice during the design stage and prevent costly errors during assembly. In addition, they can advise you on sourcing high-quality components with long warranty periods.

PCB assemblers have a range of assembly processes available to them, from wave soldering to selective soldering and hand soldering. However, it is important to understand which of these is the most appropriate for your particular application. For example, the use of hand soldering is not typically performed in high-volume assembly operations because it is difficult to perform without a designated frame for inspection and rectification.

Ultimately, the most cost-effective method for PCB assembly will depend on your specific needs and design requirements. Having an understanding of the costs involved in the assembly process will allow you to construct a budget that is accurate and reflects your specific needs. With a clear picture of the underlying costs, you can make informed decisions about where to source your manufacturing services and what pricing structure is best for you.